Heat transfer is a crucial factor in ‘cracking’ components during chemical processes. The reactions are set off in furnace tubes in which temperatures ranging between 800°C and 1,300°C are no exception. The tubes, that can reach lengths up to 20 meters, are heated by burners on the outside causing dirt to be deposited on the tube walls due to the use of fuel. The tube walls also suffer considerably from corrosion. Investigation shows that these are the two main causes of loss of heat transfer and wear of industrial furnaces.

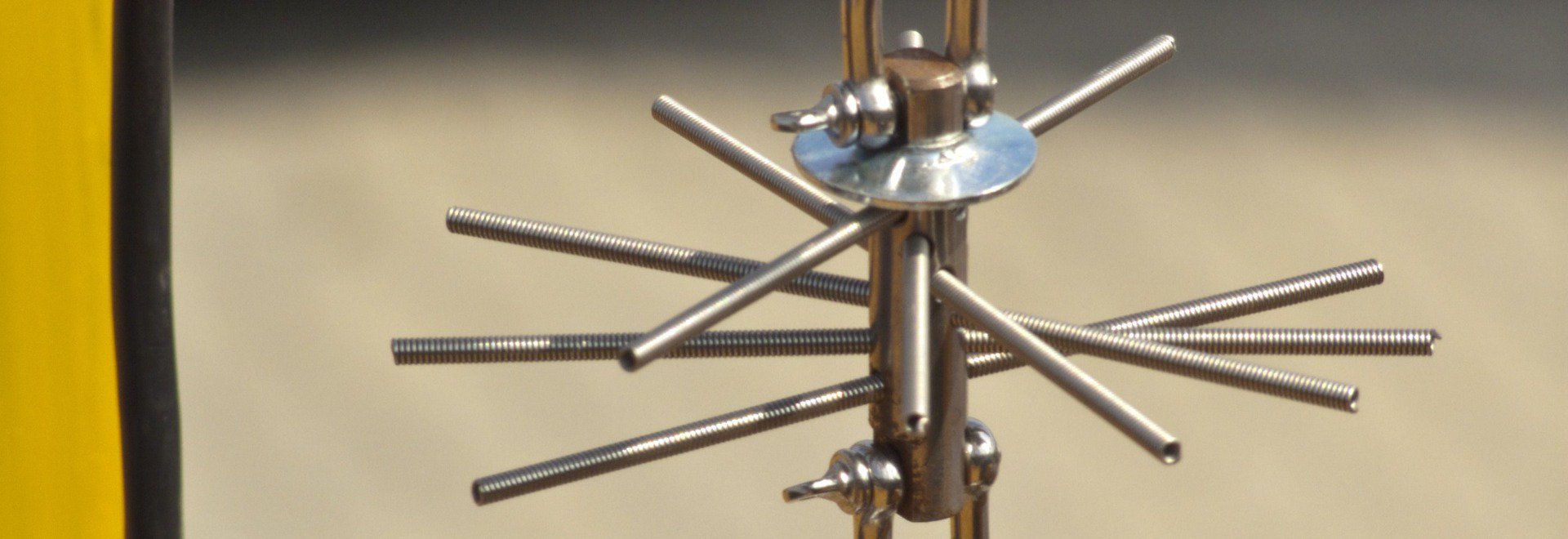

The In-Tube and Out-Tube Cleaner are the latest technology advancement in safe and efficient internal and external cleaning of reformer‐ and furnace tubes. The system is applicable for tube sizes from 3” to 10” nominal diameter. The remote‐controlled machine offers numerous advantages regarding working conditions, efficiency and safety. The In-Tube Cleaner ensures 360° cleaning solution while the Out-Tube Cleaner eliminates working at heights and minimizes personnel that are working in a confined space. Next to this time consuming and costly scaffolding is not required anymore and (compared to manual cleaning) cleaning results are improved.